Direct to Garment (DTG) printing is a relatively new technology, which is excellent for accurately reproducing photos, illustrations and intricate full colour designs.

DTG printing produces best print results on t-shirts and garments with 100% cotton content. Using DTG printing for items with a high polyester content is not currently possible.

The results for DTG Printing differ depending on what colour fabric is being printed onto:

Lights

Fantastic, full colour images with no set up costs. Excellent for short runs of less than 100 items.

Colours

A white undercoat is used when printing onto coloured garments to ensure the colours are bright and vibrant; this can mean that the print feels slightly thicker when compared to graphics printed onto lighter coloured tees.

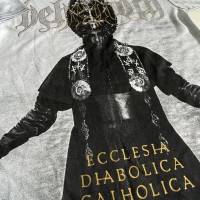

White t-shirt high quality DTG printing, Expert Horror

Design considerations for DTG

The advantage of DTG printing when compared to screen printing is the faster turnaround time and low set up costs, which makes it a more cost effective solution when printing low volume runs (up to 100). Especially when a design that features a number of different colours is required.

The main disadvantages of DTG printing are that it’s not possible to match Pantone PMS colours and the prints are not quite as vibrant when compared to those seen with screen printing where the ink adheres to the fabric.

Images must be sent as .jpg, .psd or .pdf in high resolution. This means 300dpi or higher.

Colours: CMYK

Pantone colour matching: not available

Artwork type: vector or raster graphics

File formats: .png, jpg, .ai, .eps, .pdf, .psd

Ensure the print is 100% of the intended print size.

Design and save the graphic file at 300dpi.

Make sure to save any PNG files with a transparent background.